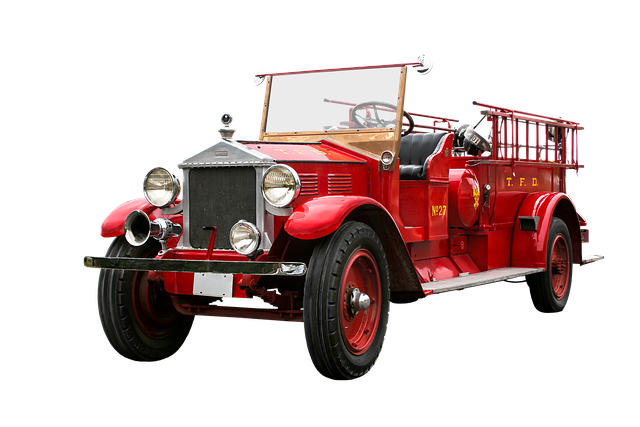

In Brownsville's vibrant fleet industry, efficient fleet truck axle repair is crucial for safe operations. Recovery straps, like chain and wire rope options, simplify repairs, reduce downtime, and align with fleet managers' needs for prompt vehicle maintenance. Choosing high-quality, durable materials ensures safety and effectiveness during repairs, with regular cleaning extending the life of these essential tools.

In Brownsville, fleet truck axle repairs are a critical aspect of maintaining road safety and minimizing downtime for commercial vehicles. This article delves into the essential role of recovery straps in this process, exploring their types, applications, and best practices for selection and use. Understanding recovery straps is key to optimizing fleet efficiency and reducing repair costs in the face of unexpected breakdowns, especially in the demanding landscape of Brownsville’s transportation sector.

- Understanding Fleet Truck Axle Repair: The Role of Recovery Straps in Brownsville

- Types and Applications of Recovery Straps for Commercial Vehicles

- Best Practices for Selecting and Using Recovery Straps to Minimize Damage

Understanding Fleet Truck Axle Repair: The Role of Recovery Straps in Brownsville

In the context of fleet truck maintenance, particularly in Brownsville, understanding fleet truck axle repair is paramount for ensuring safe and efficient operations. Axle repairs are a common yet critical aspect of vehicle upkeep, as they directly impact the stability, handling, and overall performance of trucks. Recovery straps play a pivotal role in this process, serving as essential tools during fleet truck axle repair in Brownsville. These straps provide the necessary support and security when disassembling or reassembling axles, allowing technicians to safely navigate complex repairs with minimal risk of damage.

Brownsville’s bustling fleet industry relies heavily on well-maintained trucks to keep operations running smoothly. By utilizing recovery straps, repair facilities can streamline axle repair procedures, reducing downtime and maintenance costs. This is particularly crucial for fleet managers who need their vehicles back on the road promptly. The availability of these straps ensures that repair work in Brownsville meets high standards of quality and efficiency, contributing to a robust and reliable trucking network.

Types and Applications of Recovery Straps for Commercial Vehicles

Recovery straps are an essential tool for fleet managers and owners of commercial vehicles, offering a range of options tailored to specific needs. For instance, in Brownsville, where truck axle repair services are readily available, the most common types include chain recovery straps and wire rope recovery straps. Chain recovery straps, known for their strength and durability, are ideal for heavy-duty applications, such as towing large vehicles or lifting heavy loads. They provide exceptional grip and can handle significant weight, making them a preferred choice for fleet trucks requiring axle repairs.

Wire rope recovery straps, another popular option, offer flexibility and resistance to extreme temperatures. These straps are versatile and suitable for various tasks, from stabilizing vehicles during repair processes to assisting in loading and unloading operations. In the context of commercial vehicles, they can be particularly useful for smaller fleets or businesses that require a more affordable and multi-purpose solution without compromising on quality.

Best Practices for Selecting and Using Recovery Straps to Minimize Damage

When selecting recovery straps for fleet truck axle repair in Brownsville, prioritize quality and strength. Opt for straps made from high-quality materials like durable nylon or polyester, designed to handle heavy loads without stretching or tearing. Look for a rating that indicates the maximum weight capacity, ensuring it meets your vehicle’s needs. Always inspect straps before each use; any signs of wear, such as frayed edges or broken threads, warrant replacement.

Proper usage is paramount to minimizing damage during recovery operations. Ensure adequate tension on both ends of the strap to distribute force evenly and prevent pinching or binding. Secure the strap properly around the vehicle’s frame or axle, using buckles or clamps as directed by the manufacturer. Never leave a loose end hanging; it could catch on protruding objects, causing further damage. Regular cleaning and storage in a dry, cool place prolongs the lifespan of your recovery straps.

In conclusion, recovery straps play a vital role in fleet truck axle repair, particularly in dynamic environments like Brownsville. By understanding different strap types and best practices for their selection and usage, commercial vehicle operators can minimize damage and ensure efficient fleet maintenance. Investing in the right recovery straps is key to navigating challenges related to fleet truck axle repairs in Brownsville and beyond.